High Precision Production / Machining

High Speed Milling

HSM Milling: Dynamic and Ultra-Precise High-End Machining

High-Speed Machining — or HSM milling — is one of the most advanced techniques in modern CNC machining. At Tumag, this technology plays a key role in our precision manufacturing. With many years of expertise and a cutting-edge machine park, we produce complex components that meet the highest standards in accuracy, surface quality and process stability.

What is High-Speed Machining? The difference from conventional milling

Conventional milling uses lower spindle speeds and thicker chips. HSM milling takes the opposite approach:

- very high spindle speeds,

- higher feed rates

- significantly smaller chip thickness

This results in lower cutting forces, improved heat evacuation through the chip and greater process control — all crucial for high-precision machining.

De lagere snijkrachten zorgen ervoor dat het gereedschap minder wordt belast en dat de warmte beter via de spaan wordt afgevoerd in plaats van in het werkstuk terecht te komen. Hierdoor blijven zowel het gereedschap als het materiaal in optimale conditie tijdens de bewerking, wat directe voordelen oplevert voor nauwkeurigheid en levensduur.

Benefits of HSM Milling for high-precision components

HSM frezen biedt een reeks voordelen die bij conventioneel frezen nauwelijks haalbaar zijn. Enkele belangrijke voordelen:

- Superior surface quality

High spindle speeds combined with fine chip removal produce extremely smooth surfaces.

- Exceptional dimensional accuracy

Low heat transfer to the workpiece prevents deformation and ensures stable tolerances.

- Ideal for thin-walled and delicate structures

Reduced cutting forces significantly minimise vibrations, allowing precise machining of fragile geometries.

- Increased productivity

Higher feed rates and faster cycle times lead to efficient production without compromising quality.

HSM Milling at Tumag: Engineered for technical perfection

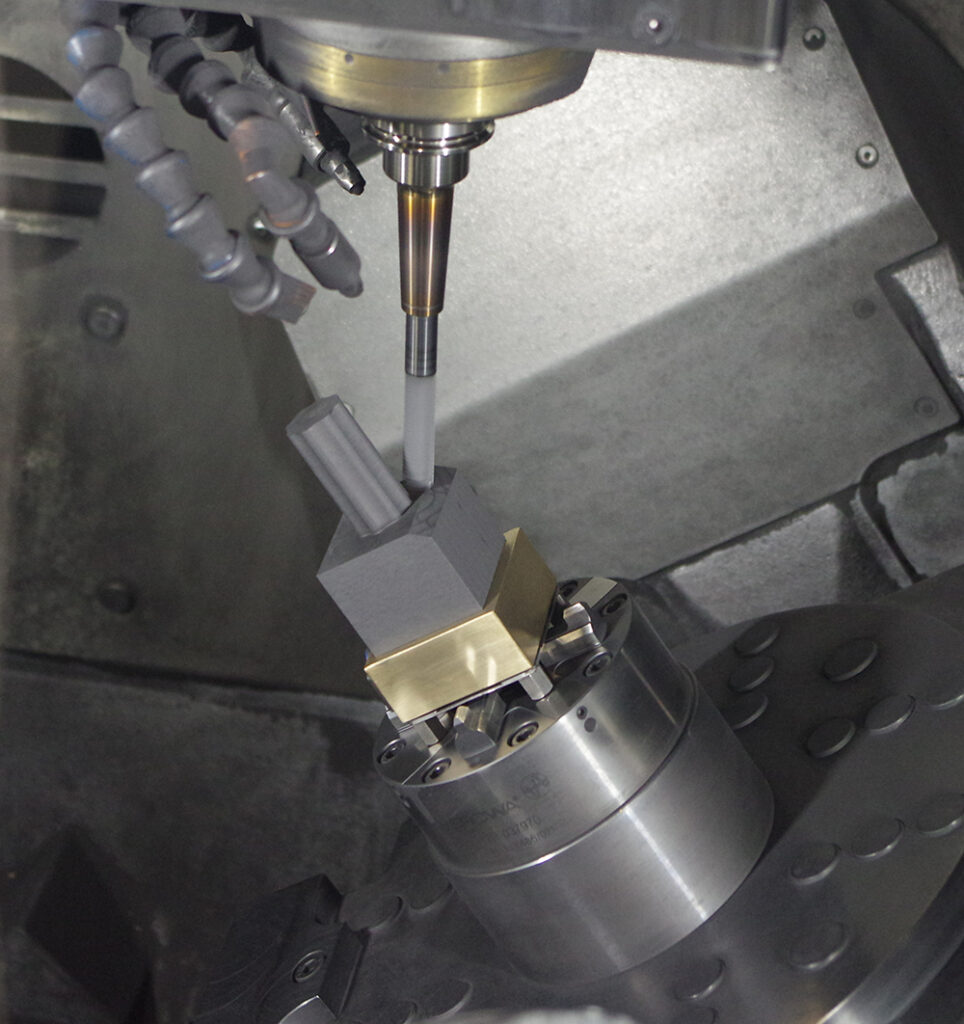

Tumag uses High-Speed Machining for parts requiring complex geometries and flawless finishes.

We machine hardened steel up to 60 HRC with ease and produce:

- graphite electrodes

- copper electrodes

- elconite electrodes

for use in our EDM machines — ensuring an optimal internal production workflow.

OPS Ingersoll 5-axis machines: precision down to 3 microns

Our OPS Ingersoll 5-axis milling centres deliver exceptional performance. With accuracies of 3 microns and spindle speeds up to 42,000 rpm, they meet the strictest standards in:

- medical applications

- high-end consumer products

- automotive

- aerospace

- mould and die manufacturing

This combination of advanced engineering and skilled operators guarantees consistent and flawless machining.

Tumag: your reliable partner for complex HSM milling projects

If your project demands extreme precision, high-quality surfaces and total process reliability, HSM milling is the ideal technique — and Tumag the ideal partner

Are you looking for a reliable partner for the production of complex components? Look no further and trust Tumag.

Services

With an in-house engineering department, we work closely with our customers' design departments to optimize the manufacturability of the product at an early stage for injection molding...

In our climate-controlled production facility, we have centralized all precision CNC machining processes to produce our high mix/low volume product range...

,

All our products are being manufactured with increasing precision and accuracy, which means the challenges for our measuring instruments continue to grow as well. During the production of precision components, it is…

We offer our injection molding expertise to our customers. With our injection molding machines, initially intended for mold optimization, validation, and testing...

For preventive maintenance, complete overhauls, or modifications to existing molds or mold parts, Tumag is the right place for you. We can also repair damaged components for you.